|

KSONIC SDN BHD

|

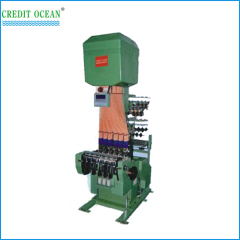

Ultrasonic Quilting Machine

| Place of Origin: | Sri Damansara |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Ultrasonic quilting Machine

Features:

~Apply to non-woven made of 100% chemical fiber as well as web by continuously ultrasonic welding. Various patterns on cloth like dot net welding, sealing and embossing can be achieved in one process.

~The unit also meets soft, bulky and multi-layer products bonded by different materials such as thermal plastic faber PE and PP.

~Performs with high production efficiency. No pre-heat is needed before operation. Bonding process can be carried out immediately after switched on.

~Various patterned products can be obtained only by changing pattern roller in a short time.

~Nice looking, uniform and strong bonding over the full web is feasible with vibrational energy given by the ultrasonic horns arranged across the roller.

~Attached with automatically indicating system which is able to detect abnormal vibration from the ultrasonic system or the feeding webs when they are broken apart. The machine will stop running to avoid further defective loss.

Applications:

Car covers, chair covers, blankets, bed covers, seat cushions, pillow case, aprons, robes, winter jackets, sleeping bags, coverlets, shoe, etc.

| Model | KQ-600 | KQ-1200 |

| Web width | Max.600mm | Max.1200mm |

| Work Speed | 5-15m/min | 5-15m/min |

| Ultrasonic System | Max. 1400W/Horn | Max. 1400W/Horn |

| Frequency 20KHz | Frequency 20KHz | |

| 3 units | 6 units | |

| Line Source | 50/60 HZ 220V/3P 5KW | 50/60 HZ 220V/3P 10KW |

| Air Pressure | 6kg/CH2 | 6kg/CH2 |

| Total Weight | 1000Kg | 1500Kg |

| Dimension (LxWxH) | 1350 x 2700 x 1900 | 1900 x 2700 x 1900 |

Related Search

Ultrasonic Quilting

Quilting Machine

Quilting Embroidery Machine

Computerized Quilting Machine

Multi Needle Quilting Machine

Computer Quilting Machine

More>>

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)